A unique taste, since the 13th century

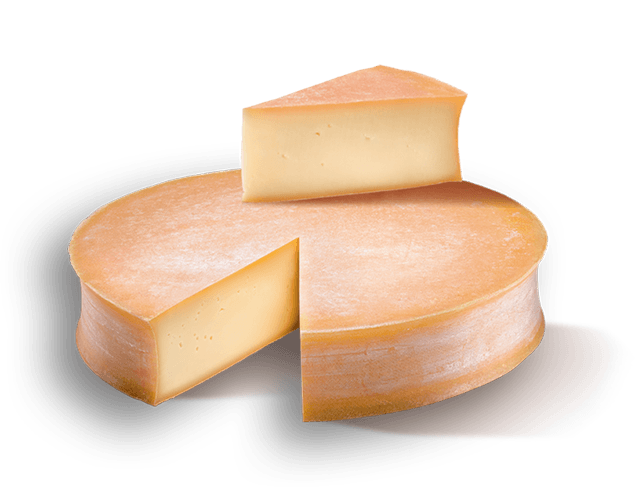

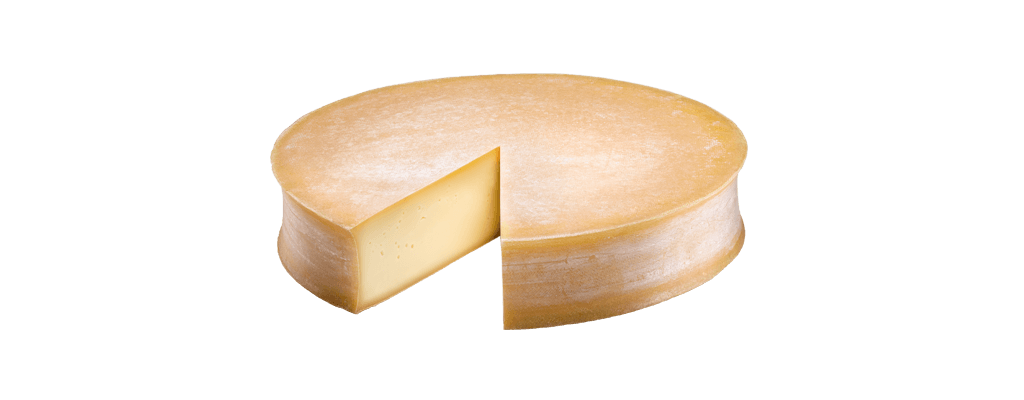

The cheese is in the shape of a flat cylindrical grinding wheel with a smooth amber-coloured crust. It weighs between 6 and 12 kg (about 10 kg on average) and is 7 to 8 cm high.

It has a soft and melting texture, ivory to pale yellow in colour, has a fruity taste coming from notes of pineapple, apricot, citrus and hazelnuts. On average 10 L of milk are needed to make 1 kg of Abondance. Production is by traditional methods: the size of the creameries is regulated and many operations on the farm are still carried out manually.